This page gives

you a quick overview of recent changes. This page gives

you a quick overview of recent changes.

11 February 2011

I starting to write a bit more, see my latest articles...

Take a look at our

Package Design tools, things are progressing very well.

7 February 2011

I have found something great and you must give it a go.

Dropbox is a

website that gives you a place to store data. It's as easy as copying files on your own system.

I find it most useful for sending big files so you can now find my

articles and out

latest program

downloads in my Dropbox folder.

Register for Dropbox now...

Lately, we are working on a design program for Fan Coil Units, Air Handlers, Aicon Packages and Evap condenser cooled packages.

Actually, there are 2 programs pacBuild - the catalog designer and pacFind - the

search program.

Read

more...

16 November 2010

It's been a while since my last update. I have been working on a big contract job for Chris Dale Spiral Systems.

Chris makes a spiral cooler that can be adapted for just about any product and any temperature range. The bread

companies seem to love him because the Dale Spiral Cooler can be found at most bakeries.

My program does the complete

design. Pick a product and specify the temperature. The program will size the spiral drum, the fan, the coil and even

create a provisional price.

31 May 2008

How do you locate a problem on a refrigeration system?

Yes, I'm on that question again. Actually, as long as you take the

right readings, it's not that difficult. What you have to understand is

basic refrigerant logic. I have just released a new program called

RefDiag that tries to identify the fault

for you and while it is in beta release, you can download it and use it for

FREE.

But still, there is no substitute for the human mind in solving complicated

problems.

So, what do you do?

Let's say that you are called to site because there is no cooling. Your

client is probably not an expert in refrigeration so you would not expect to get

a diagnosis from him but remember, he was on site when the fault occurred so

listen carefully to what he says. In particular: was there a noise, when

did it happen, has anyone else been tinkering, were

there any odd smells when it happened,

Next, look at the log book. What was the last repair?

Before diving in with your tool, think about what you have just

heard. There is a good chance that the information from the owner

and the log book could lead you to the cause.

Now, start by using your most important diagnostic tools. Your

own senses...

Look at the filters for signs of lack of maintenance, look around the

pipe system for signs of oil, look at the compressor oil sight glass,

check the liquid line sight glass, look at the fan belt for break or

wear, look for frosting on the pipes (especially at the expansion valve

outlet and suction port).

OK, once all of the obvious things are out of the way, you now have

to connect your gauge set.

The suction and discharge pressures alone are not enough. You

must measure the temperature on the suction line at the expansion valve

bulb and the liquid line temperature at the condenser outlet.

These line temperatures are so important, I am always surprised to see

that the surface temperature gauge is not that common in the refrigerant

maintenance toolbox. Measure the on-coil air temperature to both

the evaporator and the condenser.

Now we start.

What is the gauge pressure? Hold on... The gauge pressure does

not control heat flow, it is the temperature. Instead of asking about the

gauge pressure, we should ask "what is the temperature".

Depending on the refrigerant in the system, you will need to determine the

bubble point and the dew point for both the suction and discharge gauge

pressures.

The first thing that we are trying to determine here is this:

"do we have a

HP (high pressure) or a LP (low pressure) problem".

If the condenser bubble point is much higher than

the ambient air (say more than 20°C), then you have a HP problem.

If the evaporator dew point is much lower than the return air (more than

20°C), then you have an LP problem.

Low LP.

Now measure the superheat. The purpose of the expansion valve is to regulate refrigerant flow so

that the superheat at the bulb is maintained at 7.5°C.

If there is a high superheat, then the evaporator is not getting

enough refrigerant. So, where is the refrigerant?

If the sub-cooling is high, then there is a pressure drop in the liquid line.

Check for temperature drops across the sight glass and the filter drier.

The best is to measure the temperature drop from condenser outlet to expansion

valve inlet. If there is a temperature drop, then you have found the

problem. It is pre-expansion in the liquid line.

If there is no temperature drop in the liquid line, then it must be an

expansion valve fault.

If the sub-cooling was low, then there is a low charge. Notice

that we didn't just jump to this fault, it is a combination of low LP,

low sub-cooling and high superheat. You might also see bubbles in

the sight glass but remember, this is not the only reason for this

symptom).

What if the superheat is low? This means that the evaporator is

getting enough refrigerant but does not have enough capacity for the

system. This could be caused by a lack of airflow or the

evaporator could be fouled.

This is easy to check. Is there a low air temperature drop across the

evaporator (less than 6C)? Yes, then the evaporator is fouled. A

high air temperature difference (more than 10C) means that there must be a lack

of airflow. Could be just dirty filters or maybe a slipping fan belt.

High HP.

Now measure the sub-cooling. As you add refrigerant to the system, it

moves to the condenser where it is condenser to a liquid. The expansion

valve allows only the refrigerant flow needed to maintain superheat to pass

through and so any excess refrigerant will remain in the condenser. Adding

more refrigerant to the system will simply add more liquid.

What happens here is that the liquid is now backing up in the condenser and

taking up valuable condensing area. In order to achieve the necessary heat

transfer, the condensing temperature rises. Hence the HP problem.

The liquid in the condenser is now cooled more than it should (more than 7°C).

So, the high HP with the high sub-cooling means overcharge? Not

entirely, you need to check for non-condensables before concluding that there is

an over charge.

If the sub-cooling is normal (4°C to 7°C) there must be a lack of condenser

capacity. Check now for a low air temperature rise across the condenser

(less than 5°C). This would mean a blocked condenser. If the

condenser air temperature rise is high (more than 10°C), then there is a low

condenser airflow problem. Check the fan outlet, speed controller or maybe

a plastic bag across the condenser hail guard.

LP OK and HP OK

This means a lack of compressor capacity. It could just be that the

load is excessive! If not, there may be a fault on the compressor.

Now, you need to check the following:

- valves broken or not sealing properly

- valve plate gasket is too thick

- cylinders scored by broken valve fragments

- head gasket not sealing properly

- capacity regulation not set correctly

- internal safety valve not sealing

- 60Hz compressor used with 50Hz power supply

- reduced speed on direct drive system

- slide of the heat pump reversing valve is stuck

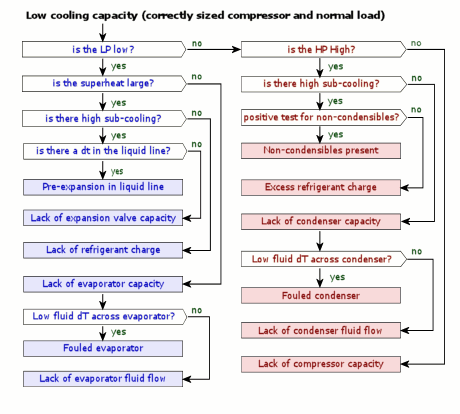

Below is a very nice diagnostic tool that comes from Patrick Kotza's

excellent REFREPAIR manual. Call me to get

the free demo CD and learn something worthwhile about refrigeration systems.

16 August 2007

Let's face it, training is a problem in South Africa. We have many

start up companies and plenty work. The difficulty is to find

refrigeration people who are actually able to locate problems. I have yet

to find a better way to learn refrigeration logic than the

Kotza training program. The program tracks

your progress and takes you through all the theory you need to be able to find

ANY problem on a faulty refrigeration system. You can repeat the course as

many times as you need and you can do it without disrupting your normal working

day.

17 July 2007

All refrigerant based programs have been updated to include the new

refrigerant library. Thanks to Tony in Hong Kong for feedback on the site

measurements of a R407C cycle.

Our new PipeNet program is almost ready for

release. Check the downloads page

soon for a fully functional evaluation release.

3 May 2007

I've been busy with a host of different things that have captured my

attention lately. PHP, CSS, JavaScript, Web design, ASP, ASP.NET, C#,

numerical methods, refrigerant properties and the Refrigeration-Engineer, to

name a few.

Some of this work is already starting to bear fruit and you will see the

results in our new program releases. Many of the items are related to web

page design. The reason is that it provides amazing flexibility in report

and data presentation.

Check out my new on-line JavaScript

moist air state calculator.

Mollier Chart includes over 140

refrigerants so that you can easily evaluate the system performance.

I have found that the

Refrigeration-Engineer forum to be an amazing source of information. If you

haven't tried it yet, give it a go. Log-on, register and start asking

questions. you will be surprised by the response.

We are finalizing the release of our PipeNet program. This is not just

an update of PipeFlow, it now has a full

graphical interface where you can build a network. In addition, the

program calculated the index run for you.

13 February 2007

I am looking for a copy of the book:

W B Gosney "Principles of Refrigeration" Published by Cambridge University Press, 1982, ISBN 0 521 23671

1

Please help me to find it. The book is out of print and not available from Amazon or any of the other on-line book

shops. Maybe you have a copy on your bookshelf and don't need it anymore.

15 January 2007

After the end of year break, I am still finding it hard to stay working for the full day. During the holidays,

I spent some time on improving my refrigerant library. For the full list, try my

MollierChart program. You will now see over 100

exotic refrigerant blends along with the common omes. Of course, these new refrigerants automatically become

available in RefSim,

LineSize,

CondUnit, aPac,

MollierChart,

Coil Simulation,

CapTube.

I have also improved the MollierChart controls to make

it easier to compare refrigerants.

17 September 2006

Plenty has happened since our last update. There are new versions of many of

the programs, mostly small fixes and improvements. Our

RefSim program now includes a professional htm

style report. The DuctNet program now has

an detailed network diagnostic and an XML import/export function.

Bruce has been doing research on coil performance and will be reporting some

interesting findings soon.

We are also happy to announce that TechniSolve has been awarded the agency

for the FrigoSim program. This is an

advanced package that allows you to design any thermal system.

10 March 2006

Nick of NF Engineering in South Africa has been giving me some good feedback

on the DuctPricer and

QuickDuct programs. Look out for an

update in the next few weeks.

Patrick Kotza has provided some good prices for the latest

refrigeration training products. I would

advise you to take advantage of the special package deal NOW.

Version 2 of the SAIRAC Technical Data CD

is due for release in August 2006. At the member price, this is a deal

that you would be crazy to miss.

The Capillary Tube selection program has been

updated thanks to information supplied by Jeff Jaffer from Canada.

Mark Setaro has prompted us to add a minimum air velocity to the static

regain method in our DuctNet program.

Thanks Mark, it is with your positive feedback that our program is improved.

13 February 2006

Like the new web site. I'm experimenting with CSS (thanks Charles

Wyke-Smith, your

book has been a great help) so you can expect some improvements here.

Check out the new PeakLoad program. It

now includes the peak time calculation. The

Room Heat load calculator also has been revised to make data input easier.

Also, take a look at the Technical Data

Manual. It's a bargain for what you get.

Our DuctNet has also had some major

improvements thanks to the feedback from Dr Alec Johansen and Mark Setaro.

18 December 2005

New program released. CableSize.

Now you can size the electrical cable with the same comprehensive software

programs that you have come to expect from us. Thanks to Dieter Bucher for

the great information.

5 September 2005

I have re-introduced the version table. The idea here is to keep you up

to date on our latest releases. Soon we will be issuing the latest update

of our RoomHeat

program. There are too many changes to discuss here but the main focus of

the update is to make data entry easier. Thanks to the encouragement of

John Kidd of YORK International, we have added some new refrigerants to our

library. You can see these in the

MollierChart program.

9 February 2005

We have written some software tools that have been included for FREE on the

SAIRAC Technical Data Manual CD.

For the amount of technical data, the CD is a good buy at R500 (South African

Rands). The software tools include

psychrometric chart plotter,

wall heat transfer coefficient calculator, duct fitting viewer. If you

would like to get a copy of these tools, send me an email request.

There has been some big improvements to our COIL

designer range and the REFSIM Refrigeration Cycle

designer. The coils now have step-by-step simulation to show the

actual air and refrigerant temperature path.

If you have not yet seen the KOTZA Refrigeration

Training Software, you don't know what you are missing. We have now

sold a number of copied in South Africa.

7 December 2004

We have been appointed as the South African agent for the

Kotza Refrigeration Training program range.

This is an impressive self help trainer that will take you from the basics to

diagnosing advanced systems.

Dr Alec Johannsen has agreed to include his Heat Load program (BSIMAC

7.0) on our web site. Future versions will incorporate links to our

Psychrometric graphics and our equipment designer tools. We hope to do

some development work together in the future.

All of our programs are being updated to include a powerful unit converter

engine. This will allow you to change the units of any value to suit your

needs. The ColdRoom program has just been

completed and will be ready for download next week. Registered users will

be able to download the updates for free.

20 June 2004

This has taken some time. For the last six months since my last update,

I have been working on the new South African Institute of Refrigeration and Air

Conditioning (SAIRAC) Technical Data Manual. Essentially, it is a

reference source for all information related to the field of HVAC&R. Take a look

at www.sairac.co.za to see what it's all

about.

The TechniSolve software range has also been revamped. Thanks to Koos

Uys in Bloemfontein and to the engineers Spoormaker & Parthers for some great

feedback.

22 December 2003

Some corrections were made to the

MollierChart program. I'm still not fully satisfied with the 2-stage

system. How about some feedback.

13 December 2003

Plenty small changes, mostly to fix WinXP problems, so we decided to make a

complete update. The coil programs DXC and CWC

have been improved considerably. Thanks to Koos Uys for some valuable

feedback in the DX coil solution.

The ACSpec program has been improved and good

news, it's FREE. So, get a copy and use it for your work

with our compliments.

Thanks to John Kidd of YORK International for improvement suggestions to

MollierChart. This now includes the

2-Stage vapor compression cycle.

26 July 2003

You will see that we have updated all the programs. This a because we

revised some of our low level routines that has needed a rebuild. We have

also improved the RoomHeat data file format.

5 July 2003

We have corrected a bug in the load routine of the

ColdRoom program. Please download the new

version.

24 June 2003

If you have been waiting for our new duct

designer, there is some good news. The beta release will be available

for download in July 2003.

24 May 2003

Our teaching tour through Canada has proved to be very successful. In

the process, we have used our software to illustrate some of the theory of

airconditioning and refrigeration. This has also resulted in a number of

suggestions from the delegates so you can expect some new releases. The

first of these is in our DuctMate calculator.

We have improved the entry selection option to accept any of the duct

dimensions. Thanks to Jan Tuszynski in Toronto for finding this one.

28 March 2003

Peter Allen of RTS Design has pointed out a snag in the new ColdRoom release.

When you install the program, we overwrite the database. This means that

we write over any changes that you may have made to your database. As long

as you know about it, you can back up the data before installing the new

version. We have fixed this problem in the version 3.080 release.

Thanks to RTS for pointing out the problem.

26 February 2003

If you have reached this page than you must know about our new website.

What a task, I never expected so many links that needed to be updated. We

will soon be releasing new program versions to update the website links.

In the meantime, we will keep the old web site active as it gets phased out.

Hennie Traut from AirTech has pointed out a problem in

RoomHeat. If you put too much fresh air

into a room, the auto design calculation has a problem balancing the

psychrometrics. For now, I have put in a check and a manual reset but it

still needs some attention.

5 January 2003

The new World Locations Database is now up

and running. Get a copy and try it out. We have received many

requests for the old DutyCalc program, so we

have now upgraded this to Windows. Try it out and let us know what you

think.

8 December 2002

We are planning to release our new duct designing

program early next year. This will have full graphic facilities and

allow you to automatically design complete ducting systems.

15 August 2002

Lots of feedback from users, keep it up. Thanks...

PipeFlow now saves the pipe specifications

in an external database that can be revised by the user. Thanks to Dusan

Stefanov of ACDD for suggestions.

LineSize has been revised to give complete

freedom of manual override selection. Thanks to Paul from Société Cifroc

in Morocco for some very useful suggestions.

Mollier and

LineSize now includes the new R22 replacement

refrigerants R407c and R410a. Thanks to DuPont for the source data.

Fluid property units have been corrected thanks to Barry Green of RTS Design

for noticing the detail.

Correction made to the Room setpoint button of

RoomHeat. Correction made to the fresh air temperature field in

ColdRoom.

14 July 2002

PipeFlow has been updated to cater for pipe

diameters up to 750mm. We have also improved the way that the price

database is stored. If you have been using the pricing facility and would

like to convert your data, please send us an email.

Thanks to response from our users, we have found that some of the input forms

are not clear with large fonts selected. We have gone through all programs

and hopefully corrected all the problems.

DuctPricer now includes user defined

types.

6 March 2002

All programs have been updated for Delphi6 and WindowsXP. In the

process, we have changed our setup.exe to produce smaller and cleaner setup

programs. There have been some minor program changes as well.

LineSize now allows evaporating temperatures

down to -60degC. All main program tool buttons include text to make

clearer.

PsyChart dry bulb scale has been modified.

19 April 2002

DuctMate has been revised to exclude

references to existing products. Have a look at the

Refrigeration Equipment Selector

added on 7 March 2002. Finally for our European users. All programs

have been updated to fixed the decimal separator problem.

We have recently developed a new range of refrigeration tools. These

include

ColdRoom load calculator, Mollier Chart,

Refrigerant line sizer, Product cooling time calculator. For more

information, visit our

Refrigeration page.

Users from Europe have pointed out that some of our programs fail to start

due to the regional settings. In Europe, the decimal and thousand

separator are reversed. We still need to find a suitable solution for this

problem but in the mean time, just set the decimal separator to '.' and the

thousand separator to ','.

23 August 2001

All programs have been updated to correct the email support with Outlook

Express. We have made significant improvements to

DuctPricer

by adding a syntax hilighter and incorporating statistics management. An

error in the PipeFlow program price estimate

has been corrected and the reporting of the price estimate has been enhanced.

18 July 2001

PipeFlow has been updated to include a price

estimate report.

12 July 2001

DuctPricer &

QuickDuct have been updated.

We have made significant improvements thanks to the feedback from our users.

The most important of these is that you can now override the automatic flange

selection. We are currently building some expert systems into our duct

pricing program. What we are doing is incorporating a statistical editor

that will allow you to use reliable history data for quick duct pricing.

This will also allow us to implement automatic error detection into your normal

DuctPricer use.

We are currently developing a building room load calculator. The

emphasis here is on simple input with clear and accurate answers.

Many of our current ColdRoom users have

asked for a Windows version. We are happy to announce that this work has

started. For the present, we are still supporting the DOS version that you

can download from this site. If you buy the DOS version, you will qualify

for a reduced price upgrade to Windows. |